The traditional method of

treating potable stored water to protect against the infestation of

Legionellosis is through the use of chemicals.

Many companies are now looking

for an alternative to chemical dosing. They want to avoid the expensive

disruption to premises, toxic presence in the water, hazards in handling

and use, and the inevitable damage to the environment that stem from

their use.

Safewater Services Ltd.

decided to investigate the potential for alternative treatment media,

which provide the required protection without the downside. Our ongoing

development and research has identified a variety of media that can

be adapted to provide protection in a range of different situations.

For the specific treatment

of potable stored water we decided to focus on two particular media

types, each able to perform the function quite adequately. However,

when used together, the complimentary effect gives significant benefits.

It is this combination of media which provides the 'active ingredient'

for the HydroMaster™ 2000 modules.

The media used are 'Special

Active Ceramics' and a 'Noble Metal Matrix'.

The following pages provide

information pertaining to each specific media and how they work, together

with some background information and Log Kill data. The media have

undergone evaluation at the WRc Evaluation and Testing Centre (NAMAS

accredited Laboratory) and have passed 'full tests of effect on water

quality'. Subsequently, they have been classified as an approved product

under the Water Byelaws Scheme and are 'suitable for use in contact

with potable water'.

Firstly, you can find some

brief information regarding Legionella Pneumophila.

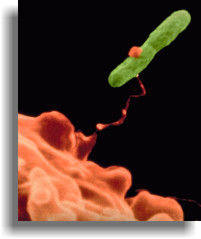

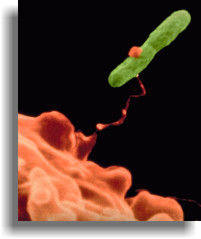

Legionella Pneumophila

What does Legionella look

like?

Legionella

Pneumophila is a Gram-negative bacterium that is widely distributed

in natural and manmade freshwater habitats. All members of the genus

have small, rod-shaped cells 1-2 µm in length and 0.5 ?µm

wide and require iron and cysteine for isolation. They will initiate

growth on artificial media only over a narrow pH range of 6.8-7.0

but can tolerate a pH range from 5.5-9.0 in natural habitats.

Legionella

Pneumophila is a Gram-negative bacterium that is widely distributed

in natural and manmade freshwater habitats. All members of the genus

have small, rod-shaped cells 1-2 µm in length and 0.5 ?µm

wide and require iron and cysteine for isolation. They will initiate

growth on artificial media only over a narrow pH range of 6.8-7.0

but can tolerate a pH range from 5.5-9.0 in natural habitats.

When Legionella Pneumophila was first isolated, it was found to be

only distantly related to other bacteria and was placed in its own

family, the Legionellaceae. DNA-DNA hybridization experiments and

16S rRNA studies have shown that the species of Legionella are closely

related to one another but distantly related to other bacteria. The

most closely related groups are the purple sulphur bacteria, the Enterobacteriaceae

and Pseudomonas.

Legionella Pneumophila was

identified in 1979 following an outbreak of 'Legionnaire's Disease'

caused by the bacterium. It was later learned that previous outbreaks

of Legionnaire's disease had occurred as early as 1957. Legionella

Pneumophila was isolated in 1947 in a guinea pig that had been inoculated

with blood from a patient with an unknown disease.

Legionnaires Disease

The first identified outbreak

of Legionnaires Disease occurred during a Pennsylvania State Convention

of the American Legion in 1976. 182 cases resulted in 29 deaths within

the hotel. 38 cases were reported amongst passers by, resulting in

a further 5 deaths. In recent years 200 - 300 cases of the disease

have been reported each year in England and Wales. The majority of

outbreaks are associated with buildings such as; Hotels, Factories,

Hospitals, Nursing Homes and Office Blocks.

More research has been carried

out in the United States where, according to the OSHA (Occupational

Safety and Health Administration - part of the U.S. department of

Labour), Legionnaire's disease is considered to be fairly common and

serious, and the Legionella organism is one of the top three causes

of sporadic, community-acquired pneumonia.

Because it is difficult

to distinguish this disease from other forms of pneumonia, many cases

go unreported. Approximately 1,000 cases are reported annually to

the CDC (Centre for Disease Control and Prevention), but it is estimated

that over 25,000 cases of the illness occur each year and cause more

than 4,000 deaths.

This is in excess of 25

times the number of reported cases, which would indicate that some

5000 - 7500 cases in England and Wales is, perhaps, a more accurate

figure. There are sources in the UK that believe the true problem

attributable to all of the 20+ different varieties of Legionella linked

with human diseases, could be significantly higher than this.

In the UK 180,000 people

die from all of the different varieties of pneumonia each year. As

many cases apply to people in susceptible groups (such as the elderly,

smokers, alcoholics, cancer sufferers and other immuno-suppressed

patients) rarely is a full investigation of the true cause of the

pneumonia carried out.

How do people contract Legionella?

The most popular theory is that the organism is aerosolised in water

and people inhale the droplets containing Legionella. However, new

evidence suggests that there is another way of contracting Legionella.

It appears that "aspiration" may be the way the bacterium

enters into the lungs. Aspiration means choking such that secretions

in the mouth get past the choking reflexes and instead of going into

the oesophagus and stomach, mistakenly, enter the lung.

Special Active Ceramics

What is an 'active' ceramic.

Most basic ceramics such

as glass, porcelain, clay ware, and brick, are based on natural aluminium

silicates, which are 'inactive' electrical and thermal insulators.

New technology has led to a range of 'special' or 'active' ceramics

which display physical properties of semi-conductivity, thermal and

ultra-sound conductivity, magnetic properties, and light emission,

achieved by the addition of various selected transition elements and

sintering at very high temperatures.

These 'active' ceramics,

used for the treatment of water and other liquids, are produced as

spheres, having a layered structure around a central nucleus or 'seed'

and a complex open structure, which can exchange ions (zeolyte), through

minute electrolytic cells, which become active when in contact with

an electrolyte such as water.

The material of the spheres

is approved by the Water Research Centre under the Water By-laws scheme

for use in contact with potable water.

They present no hazard to

health or body in either their use, handling, storage or transportation

(COSHH Regulations and Occupational Exposure Limits).

How Do They Work?

Most bacteria have a short

life expectancy and, deprived of nutrition or the wrong environmental

conditions, quickly expire. They reproduce by one of two methods;

binary fission, where individual cells continually divide into two

identical cells, and sexual, where two cells merge before producing

progeny by division or 'budding'. The function of any bacteriastat

is to prevent or inhibit both types of reproduction.

Disinfection can be achieved

by physical or chemical means, involving destruction of the information

required by the cell to survive (the DNA complex), or of the membrane

enveloping the cell. Physical methods include heat (wet or dry), electro-magnetic

radiation (infra-red, ultra-violet, ? & ? rays), ultra-sound etc.

These can kill all living microorganisms, the result being termed

`Sterilisation'. Chemical methods include strong oxidising agents

such as chlorine and its oxides, bromine, iodine, hydrogen peroxide

and its derivatives. Also, heavy metal ions such as those of copper,

silver, mercury etc. and specific organic compounds such as pesticides,

phenolic compounds, organo-chlorine and phosphorus. These tend to

act in a general fashion by attacking the cell as a whole, or selectively

by altering the genetic structure, and can vary in strength from mild

to strong. These are termed `Disinfectants'.

Active ceramics are a recent

development in the production of specially designed, dedicated ceramics.

When immersed in water these 'Active Ceramics' display physical properties

of semi conductivity, magnetic properties and light emission (in the

far infra red spectrum).

The effect is similar to

a miniature electric cell, the current flow causing hydroxyl ions

(OH) to convert to oxygen gas (O2). At the same time the formation

of hydroxyl and anolyte result in a neutral Ph.

The radiation emitted by

the spheres in the far infra red region of the electro magnetic spectrum

is too low to cause sterilisation, but is sufficient to excite the

molecules in the water, thereby stimulating the oxidisation process.

The oxidisation (and production

of chlorine) by the electrolysis of water acts as a potent disinfectant,

with the anaerobic bacteria (amongst which are Legionella and E.Coli)

being the most sensitive to attack and therefore most quickly controlled

or eliminated. Aerobic bacteria can also be affected but the protective

enzymes they produce considerably extend the time taken to achieve

the same result.

Bacteria are attracted by

the chemical activity and extensive substrate of the Active ceramics

where they attach themselves to the surface. There the products of

the electrolytic process destroy the D.N.A. and/or the membrane enveloping

the cell, whereupon their ability to thrive and reproduce is ended.

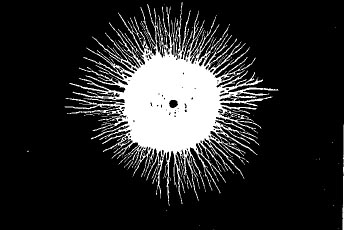

Far Infrared Emissions

from a Single Special Active Ceramic Sphere

(Autoradiograph on a photographic emulsion)

The Electro-Chemical Action of 'Active' Ceramic Spheres

Application of an electrical

voltage of a certain value across two inert electrodes immersed in

water will cause current to flow involving ions (not electrons as

in metals and semiconductors), the positive hydrogen ions (H+) collecting

at the Cathode (-ve) where electrons convert the ions to hydrogen

gas (H2). This is only possible if a corresponding process takes place

at the Anode, which transfers electrons from the water, achieved by

the Hydroxyl ions (OH) converting to oxygen gas (O2). Impurities in

the water increase the electrical conductivity of the water and reduce

the potential at the electrodes.

The region around the cathode

is called the catholyte and is generally alkaline (high pH) due to

the formation of the hydroxyl, while the region around the anode is

the anolyte, which is acidic (low pH) and is where the oxidising entities

are formed. When catholyte and anolyte mix the result is pH which

is neutral, while some of the active species lose their potency.

Using natural water with

a degree of mineralization, for example, NA+, K+, Ca+, Mg2+, C1-,

SO42-, HCO32-, etc..

ANOLYTE

pH = 3 '7 ORP = +700 '+1200

mV

Active products synthesised:

HO2, HO*2, O3, O*2, H2O2, O2, H+ (H3O+), O*, OH*, Cl2O, C1O2,

HC1O, C1O*, C1* C12, S2O82-, C2O62-

.

CATHOLYTE

pH = 10 '11 ORP = - 500

' - 800 mV

Active products synthesised:

NaOH, KOH, Ca(OH)2, Mg(OH)2, HO*, H3O2*, HO*2, H2O*2, O*2, HO-, O22-,

O2-.

Note: * = free radical

Properties

The Active Ceramics transmit

radiation, in the far-infra red region of the electro-magnetic spectrum,

of low intensity and energy (of relatively low energy compared, say,

to that of ultra-violet), too low to cause sterilisation but capable

of exciting the molecules of water by vibration and rotation, and

so increasing their mobility (by lowering viscosity) and thereby facilitating

the oxidising process.

However, it is the electro-chemical

property, which achieves disinfection. Over the surface of the ceramic

minute cells are formed, comprising pairs of cathodes and anodes,

where water is electrolysed, splitting into its component hydrogen

and oxygen albeit in a complex manner.

While the hydrogen readily

escapes, the oxygen so produced provides a powerful oxidising reagent

capable of inhibiting the growth of micro-organisms and, indeed, killing

them. This is akin not only to the physical sterilisation performed

by heat, ultra-violet, ? and ? radiation and ultra-sound, but also

the disinfecting properties of such powerful oxidants as chlorine,

bromine, iodine, chlorine dioxide, peroxide and ozone, without leaving

the latter group's obnoxious and often hazardous residues.

The significant advantage

of Active Ceramics over other (non sterilising) products currently

available for prevention of the infestation of bacteria is that the

electrolytic process (Bactericidal action) begins immediately upon

immersion, and is continuous and consistent thereafter, whatever the

operating conditions. This compares with the effects of the most commonly

used chemical treatments, which are transient and uncertain, requiring

constant monitoring and re-dosing to ensure protection.

As the pH of the water treated

is changed towards neutral the deposit of scale is

immediately inhibited, and removed over time, down stream of the influence

of the

Active Ceramics. This is shown by the formation of fine deposits in

waters of measurable 'hardness' (lime scale).

Disinfecting Capability

Most common disinfectants,

such as sodium hypochlorite, take a significant time to kill the total

number of microorganisms present, depending on their size and structure.

For example, a 1% (10,000 mg/litre) solution of free chlorine can

take up to 10 minutes to achieve 100% eradication, while the normal

1mg/litre in municipal water supplies can take as much as 24 hours

to give total kill, by which time it has been considerably diminished

by side reactions.

In comparison, the effectiveness

of one of the 'Active Ceramic' formulations is demonstrated in the

following graph:

Note: Other formulations

achieve 100% kill in 24 hours but at different rates and microorganism

selectivity.

The Noble Metal Matrix

Introduction

A Noble metal (such as the

silver used in our matrix) is chemically inert or inactive, especially

toward oxygen. It has superior properties (e.g. highly resistant to

corrosion) and is usually of a relatively higher value than so called

base metals (such as iron), which tend to be of comparatively low

value and have inferior properties (such as lack of resistance to

corrosion).

In a world concerned with

the spreading of virus and disease, silver is increasingly being tapped

for its bactericidal properties and used in treatments for conditions

ranging from severe burns to Legionnaires Disease.

While silver's importance

as a bactericide has been documented only since the late 1800s, its

use in purification has been known throughout the ages. Early records

indicate that the Phoenicians, for example, used silver vessels to

keep water, wine and vinegar pure during their long voyages. In America,

pioneers moving west put silver and copper coins in their water barrels

to keep it clean.

In fact, "born with a silver spoon in his mouth" is not

a reference to wealth, but to health. In the early 18th century, babies

who were fed with silver spoons were healthier than those fed with

spoons made from other metals, and silver pacifiers found wide use

in America because of their beneficial health effects.

Recent research compared

silver-copper ionisation with the use of high temperatures to destroy

bacteria. Contaminated cold water re-infected the hot water system

even when temperatures in hot water heaters reached as high as 60

degrees Centigrade. But experiments showed that even at lower water

temperatures, ionisation of soft water with silver and copper ions

was effective against the bacteria.

'Ionisation showed better results' said Nigel Pavey, principal research

engineer for BSRIA Water Services Technology Centre in Berkshire and,

to make certain its benefits are widespread, 'there should be more

emphasis on copper-silver ionisation in legislation'.

How It Works

Our unique Noble Metal Matrix

(Patent Pending) is comprised of numerous separate woven strands of

wire manufactured from pure silver and copper. These strands are then

compressed into a matrix format that has a considerable surface area,

yet does not restrict the flow of water into which it is immersed.

Once in contact with water the differences in electromotive series

between the metals cause the release of minute quantities of the metal

ions allowing for their uptake by any microorganisms.

The common methods of treatment

(adding dilute solution or releasing the metals electrochemically)

are fraught with problems, particularly in controlling the final concentrations

in the treated water, as both copper and silver are toxic to humans

and other vertebrates. Controlling the final concentrations using

electrochemical ionisation in areas of hard water is particularly

difficult due to electrode scaling.

The Noble Metal Matrix offers

an improved disinfection method, overcoming many of these problems,

by releasing a strictly controlled quantity of ions into the water.

For over two millennia it

has been known that, copper and silver purified water. It was found

that storage of water in copper vessels prevented the growth of algae,

while silver kept the water potable. However, it was only a hundred

years ago that the oligodynamic action of such metals on biological

processes became understood.

It is now known that silver

attaches to sulphur atoms which link the helices of DNA in individual

cells of bacteria thus preventing replication and growth, while copper

has a pronounced effect on the photochemical reproduction of algae

and certain bacteria. It is known that there is synergism between

the two metals, as with other chemical species, which further oxidise

and complex the metals' ions rendering them more soluble in water.

Disinfecting Capability

The effectiveness of silver

as a bactericide is well known and researched. Tests carried out using

our Noble Metal Matrix showed the following results. At all times

the levels of silver and copper in the water remained well within

The Drinking Water Directives.

The Benefits of combining

the two media

Both the 'Special Active Ceramics' and the 'Noble Metal Matrix' are

independently capable of providing protection against bacterial infestation

and, subsequently, satisfying a 'Duty of Care'.

However, there are limitations

in the use of each individually. For instance, each individual media

demonstrates variations in the kill rate of the different bacteria.

The 'Special Active Ceramics' treat the stored water tanks but have

little residual downstream effect. They will stop the formation of

bio-film but not that of algae. The 'Noble Metal Matrix' doesn't balance

the pH of the water nor will it prevent the formation of biofilm.

Legionella

Pneumophila is a Gram-negative bacterium that is widely distributed

in natural and manmade freshwater habitats. All members of the genus

have small, rod-shaped cells 1-2 µm in length and 0.5 ?µm

wide and require iron and cysteine for isolation. They will initiate

growth on artificial media only over a narrow pH range of 6.8-7.0

but can tolerate a pH range from 5.5-9.0 in natural habitats.

Legionella

Pneumophila is a Gram-negative bacterium that is widely distributed

in natural and manmade freshwater habitats. All members of the genus

have small, rod-shaped cells 1-2 µm in length and 0.5 ?µm

wide and require iron and cysteine for isolation. They will initiate

growth on artificial media only over a narrow pH range of 6.8-7.0

but can tolerate a pH range from 5.5-9.0 in natural habitats.